Description:

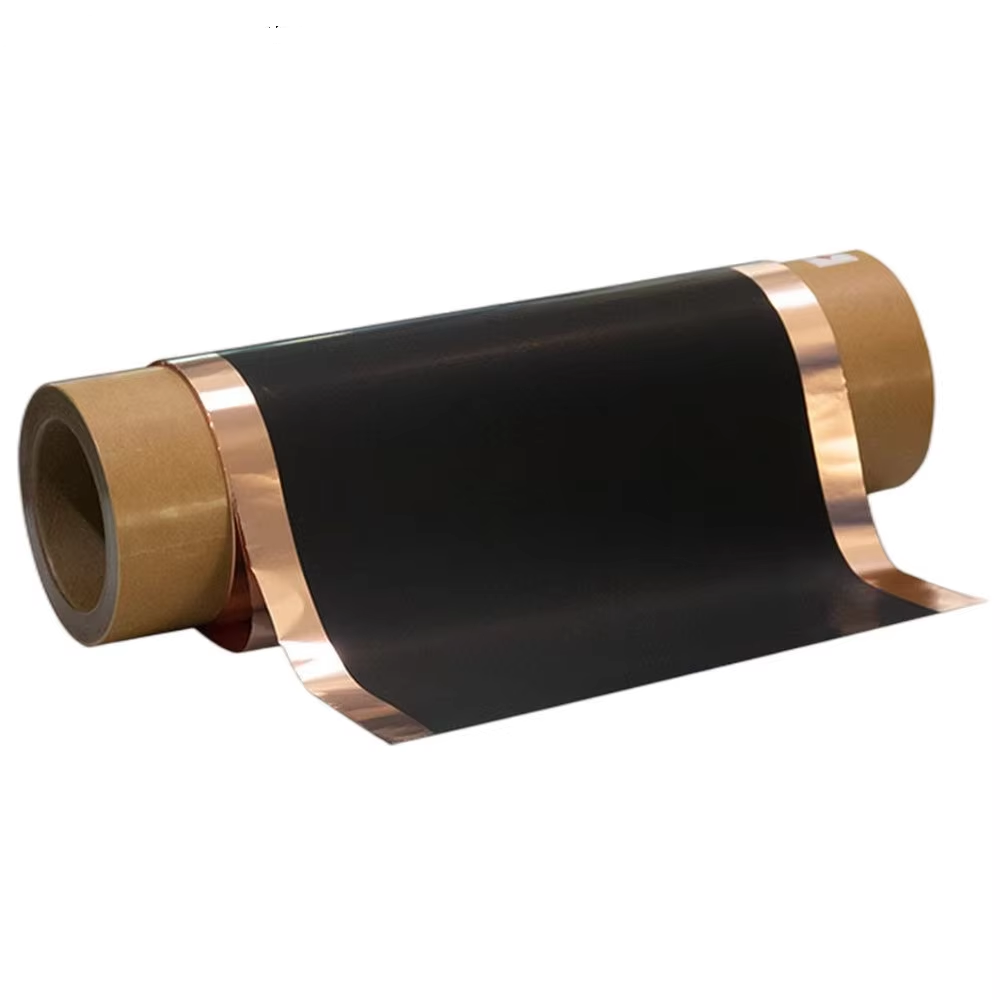

Introducing our Graphite Copper/Aluminum Foil, an innovative material designed for optimal EMI shielding and thermal management in electronic applications. This advanced foil combines the conductive properties of graphite with copper or aluminum, providing superior performance in high-demand environments.

Basic Information

- Model: TMS-DC0134

- Type: Conductive Carbon-Coated Copper Foil

- Material Composition: Copper Alloy

- Category: Power Tool Parts

- Customization: Available

- Surface Treatment: Coating

- Type: Rolled Material

- Double-Sided Coating Thickness: 1 micron per side

- Total Width: 260mm

- Total Thickness: 16 microns

- Density: 0.5 g/m²

- Application Overview: Primarily used for lithium battery anode substrates

Detailed Specifications

General Attributes

- Product Name: Conductive Carbon-Coated Copper Foil

- Double-Sided Coating Thickness: 1 micron per side, providing uniform conductivity

- Density: 0.54 g/m²

- Surface Resistance: Less than 30 ohms/25μm²

- Tensile Strength: ≥ 150 MPa

- Elongation: ≥ 0.5%, ≤ 6%

- Surface Wetting Tension: > 50 dyne/cm

- Copper Foil Thickness: 16 microns

- Coating Width: 220mm

- Total Width: 260mm

- Total Thickness: 18 microns

- Length: Approximately 80 meters (packaged by weight)

Key Features and Advantages

- Enhanced Conductivity and Reduced Internal Resistance: The conductive carbon-coated copper foil significantly enhances the overall conductivity of lithium-ion batteries. It helps to improve battery performance, extends battery life, and reduces internal resistance.

- Increased Mechanical Strength and Durability: This carbon-coated copper foil boasts higher tensile strength and durability, helping to prevent short circuits caused by dendrite growth, thus offering better mechanical stability.

- Improved Electrode Coating Strength: The functional coating layer on the carbon-coated copper foil enhances the adhesion of active electrode materials, thereby improving the cycle performance and reliability of the battery during charge and discharge.

- Higher Discharge Capacity and Battery Life: This material supports greater discharge capacity, optimizes battery efficiency, and extends the lifespan of lithium-ion batteries.

Coating Technology: Conductive Carbon Coating

This product utilizes advanced conductive carbon coating technology to ensure exceptional performance:

- Uniform Nano-Graphite and Carbon-Coated Particles: The evenly distributed carbon particles on the copper foil improve static conductivity, effectively collecting microcurrents from active materials and significantly reducing contact resistance between electrode materials and current collectors.

- Reduced Need for Adhesive: The conductive coating reduces the amount of adhesive required between the positive/negative electrode materials and the current collector, enhancing the overall electrochemical performance of the battery.

- Coating Options: Available in water-based (aqueous system) and oil-based (organic solvent system) coating options to accommodate different manufacturing needs.

Application Fields

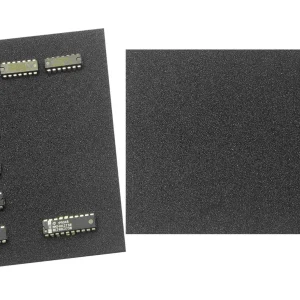

This conductive carbon-coated copper foil is widely used in the lithium battery field, specifically suitable for battery anode substrates, meeting the stringent requirements of the following industries:

- Insulating Materials: Extensively used in high-performance electronic insulation.

- Electronic Adhesive Products: Suitable for various electronic special adhesive pads, double-sided adhesive tapes, and other electronic adhesive materials.

- Automotive and Consumer Electronics: Used in batteries for smartphones, laptops, electric vehicles, and more.

Storage and Shelf Life

To maintain the product’s integrity and performance, it is recommended to follow these storage guidelines:

- Storage Environment: Control temperature between 5°C and 45°C, with humidity ≤95%, and avoid direct sunlight exposure.

- Shelf Life: When unopened and stored under the prescribed conditions, the shelf life is 6 months.

Usage Precautions

For optimal performance, please follow these guidelines during use and handling:

- Storage of Moisture-Sensitive Materials: It is advisable to store in a vacuum environment to prevent moisture absorption and material degradation.

- Pre-Use Treatment: Before use, heat the sample in a vacuum oven to 180°C to remove moisture, ensuring optimal performance.

Summary

The conductive carbon-coated copper foil is an innovative high-performance material designed for lithium battery anode substrates. This material can replace traditional aluminum foil, enhancing electrical conductivity, reducing internal resistance, and offering higher mechanical strength. Its unique properties help improve the discharge capacity of lithium-ion batteries and significantly extend battery life. Whether for commercial manufacturing or specialized applications, this product meets the stringent requirements of modern energy storage technology.

For detailed product information, customization options, or to place an order, please feel free to contact us. We look forward to collaborating with you and providing the best solutions for your application needs.

Reviews

There are no reviews yet.