Die cutting technology machines have become integral to modern manufacturing, revolutionizing how materials are processed and shaped. These machines have a rich history that reflects technological advancements, industry demands, and evolving manufacturing practices. In this blog, we will explore the historical evolution of die-cutting machines, their diverse applications across various sectors, the latest innovations transforming the industry, and what the future holds for this vital technology.

A Historical Overview of Die Cutting technology Machines

The origins of die-cutting can be traced back to the late 19th century when manufacturers began seeking ways to automate the cutting process. Initially, die-cutting was a manual process involving hand tools and templates, which limited production speed and precision. The first mechanical die-cutting machines emerged around the 1880s, allowing for faster and more consistent cutting.

Early Innovations

The introduction of the mechanical press marked a significant turning point in die-cutting technology. These presses utilized mechanical force to shape materials accurately and efficiently. By the early 20th century, the use of steel dies became common, enabling manufacturers to produce intricate designs and shapes with greater ease. As industries expanded, the demand for faster production methods grew, leading to further innovations in die-cutting machinery.

The Rise of Electric and Automated Machines

In the mid-20th century, the advent of electric-powered machines transformed the die-cutting landscape. Electric die-cutting machines significantly increased production speeds and reduced the manual labor required in the process. Automation further revolutionized the industry, allowing for programmable machines that could execute complex cutting patterns with minimal human intervention. This shift not only improved efficiency but also enhanced the accuracy of cuts, ensuring consistency across large production runs.

The Versatility of Die-Cutting Machines

Today, die-cutting machines are utilized in a wide range of industries, each with specific applications that demonstrate the versatility of this technology. Here are some key sectors where die-cutting machines play a critical role:

1. Packaging Industry

In the packaging sector, die-cutting machines are crucial for producing boxes, cartons, labels, and other packaging materials. The ability to create customized shapes and sizes allows companies to design packaging that not only protects products but also enhances brand visibility. With the growing trend of sustainable packaging, die-cutting machines are also being used to create eco-friendly options that minimize waste.

2. Automotive Sector

The automotive industry relies heavily on die-cutting machines for producing components such as gaskets, seals, and insulation materials. These parts must meet strict specifications to ensure quality and safety. Die-cutting machines enable manufacturers to create precise components that fit seamlessly into vehicles, contributing to overall performance and reliability.

3. Electronics and Appliances

In the electronics industry, die-cutting machines are essential for producing insulation materials, protective covers, and circuit boards. The precision offered by die-cutting is vital for ensuring that these components meet the stringent standards required for safety and functionality.

4. Textile and Apparel Industry

Die-cutting machines are increasingly used in the textile and apparel industry for cutting fabrics into patterns. This method not only increases production speed but also reduces material waste, making it an eco-friendly choice. Whether for garments, upholstery, or accessories, die-cutting machines streamline the cutting process, allowing manufacturers to meet tight deadlines while maintaining quality.

5. Arts and Crafts

Beyond industrial applications, die-cutting machines have found a place in the arts and crafts sector. Hobbyists and professionals alike use these machines to create intricate designs for scrapbooking, card making, and other creative projects. The availability of customizable dies allows users to express their creativity while achieving professional-looking results.

Technological Advancements in Die-Cutting Machines

As industries evolve, so too do the technologies that drive die-cutting machinery. Here are some of the most significant advancements shaping the future of die-cutting:

1. Digital Die-Cutting Technology

One of the most exciting developments in die-cutting is the emergence of digital die-cutting machines. These machines utilize digital files to execute cuts, eliminating the need for physical dies in many cases. This technology allows for rapid prototyping, customization, and the ability to produce small runs of unique designs without the high costs associated with traditional die production. As customization becomes more sought after in various industries, digital die-cutting is becoming increasingly relevant.

2. Automation and Industry 4.0

The integration of automation and Industry 4.0 principles in die-cutting machines is transforming manufacturing processes. Smart die-cutting machines can communicate with other equipment and systems, enabling real-time data collection and analysis. This connectivity allows manufacturers to monitor production efficiency, predict maintenance needs, and optimize workflows, ultimately leading to reduced downtime and increased productivity.

3. Eco-Friendly Innovations

Sustainability is a growing concern across all industries, and die-cutting technology is no exception. Many manufacturers are now focusing on eco-friendly practices, developing die-cutting machines that minimize material waste and energy consumption. Innovations such as the use of recyclable dies and materials, as well as energy-efficient machinery, are becoming more common. These advancements not only benefit the environment but also help companies meet consumer demand for sustainable products.

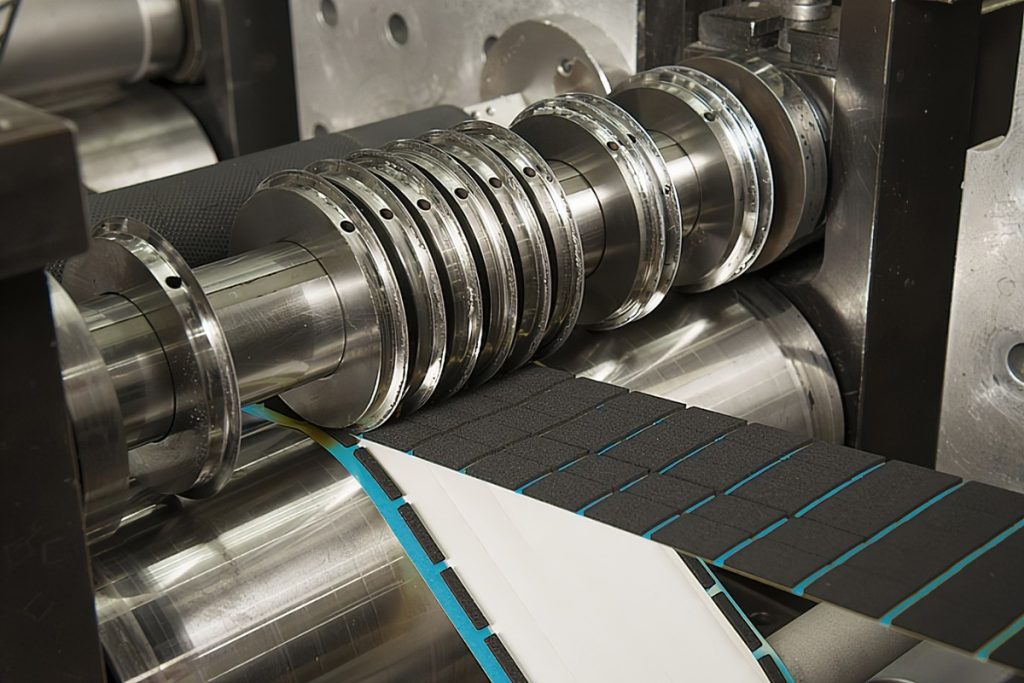

4. Enhanced Precision and Speed

Recent technological advancements have led to improvements in the precision and speed of die-cutting machines. High-speed rotary die-cutters and flatbed die-cutters are designed to operate at faster rates while maintaining tight tolerances. This increase in efficiency allows manufacturers to meet the demands of high-volume production without sacrificing quality.

The Future of Die-Cutting Machines

As we look to the future, the die-cutting industry is poised for continued growth and innovation. Several trends will likely shape the evolution of die-cutting machines:

1. Increased Customization

With consumers increasingly seeking personalized products, the demand for customized die-cutting solutions will continue to rise. Manufacturers will need to invest in flexible die-cutting systems that can accommodate varied designs and rapid changes in production requirements.

2. Integration of AI and Machine Learning

Artificial intelligence (AI) and machine learning are expected to play a significant role in the future of die-cutting technology. These technologies can optimize cutting processes by analyzing data to improve efficiency, reduce waste, and predict machine performance issues before they occur.

3. Greater Focus on Sustainability

As sustainability becomes a core value for businesses and consumers alike, die-cutting manufacturers will prioritize eco-friendly practices. Innovations in materials, energy-efficient machinery, and waste reduction techniques will be essential in meeting sustainability goals and consumer expectations.

4. Expanding Applications

The versatility of die-cutting machines will lead to new applications across various industries. As manufacturing processes evolve, we can expect to see die-cutting technology utilized in areas such as construction, healthcare, and renewable energy, further demonstrating its adaptability and importance.

Conclusion

Die-cutting machines have come a long way from their humble beginnings, evolving into sophisticated tools that play a crucial role in modern manufacturing. With their wide-ranging applications and continued advancements in technology, die-cutting machines are poised to remain integral to various industries. At [Your Company Name], we are committed to staying at the forefront of die-cutting technology, providing our clients with innovative solutions that meet their production needs. Whether you’re in packaging, automotive, electronics, or any other sector, our expertise in die-cutting machinery can help you achieve your manufacturing goals.

If you’re looking to invest in die-cutting technology or have any questions about our products, please contact us today. Together, we can shape the future of your manufacturing processes!